Lithiumate™ Manual |

|

index Lite BMS master description Principles of operation

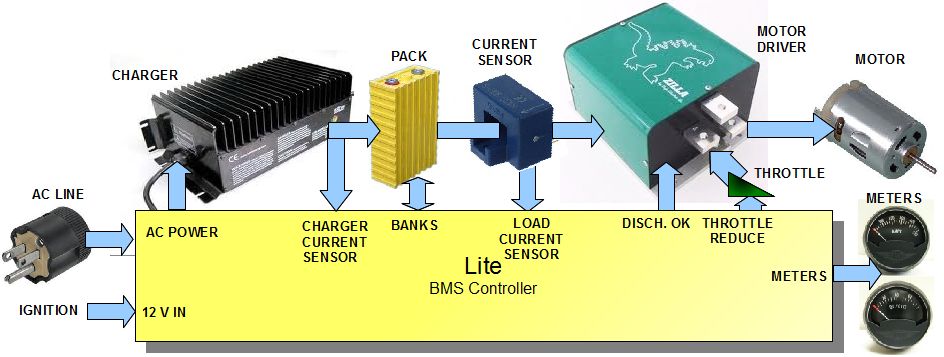

The typical Li-Ion EV traction system consists of:

During set-up, the BMS master is connected to a Windows computer to configure and monitor the BMS.

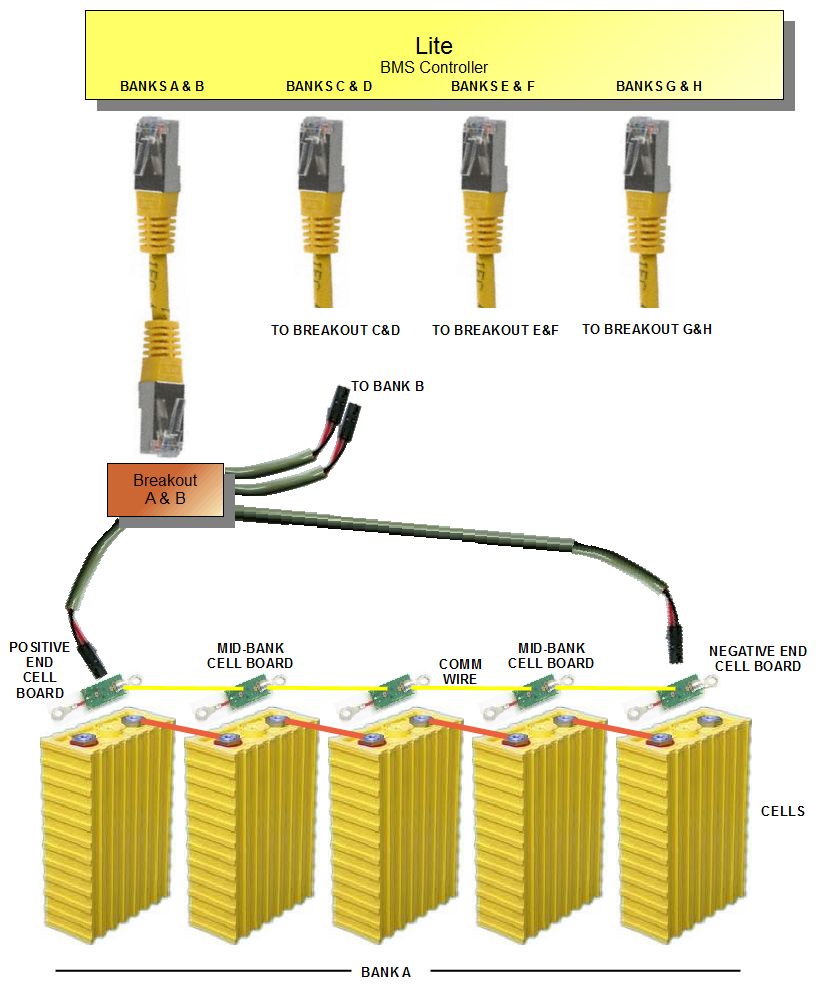

The BMS master interfaces to the cells, divided into banks. It can handle up to 8 banks of cells. The BMS master communicates with the banks through up to 4 shielded RJ45 cables; each cable handles 2 banks. At the far end of each cable, a breakout adapter goes from the single RJ45 cable, to 4 individual, small cables. Each small cable is a shielded pair, terminated with a 2-pin connector. Two of those 4 small cables are used for one bank (one to the most positive cell of the bank, one to the most negative one) and the other 2 cables are used with another bank. The BMS sends a serial digital stream (with a proprietary format) through the RJ45 cable, through the breakout and through a small cable, to a 2-pin connector on the positive end cell board. The positive end cell board (mounted on the most positive cell of the bank), provides electrical isolation between the incoming cable (which is referenced to ground) and its own electronics (which are referenced to the high voltage of the battery). The cell board detects and executes any commands in the serial stream, adds data to the serial data stream, and passes it to the next, more negative cell board. The communication between cell boards is through a single wire link. The next cell board (a mid-bank board) receives data form the positive end cell board through the single wire link. Just like the positive end board, it executes commands, adds data to the stream, and passes it to the next cell board. The following cell boards operate the same way, down to the last cell board in the bank. The negative end cell board (mounted on the most negative cell of the bank), performs the same functions as the other cells. But, instead of passing the serial stream to another cell board, it isolates it, and it passes it to its 2-pin connector. A small cable, connected to the 2-pin connector on the negative cell board, carries the return serial stream back to the breakout, through the RJ45 cable, and back to the BMS master.

Other than the isolation at the positive and negative end cell boards, all the cell boards are identical. There is no need to configure each cell board to give it a unique ID, to tell it where it is placed along the bank. Instead, the BMS master does that, on the fly, at power-up. Therefore, cell boards may be interchanged without a problem. Through the serial stream, the BMS master is able to tell the cell boards to measure their cells' voltage and temperature, and to turn on their balancing loads. Each cell boards adds its measurement results to the data stream and passes it to the next cell board, and then back to the BMS master. The BMS master gathers the data from all the cell boards, and calculates various key parameters:

Then, the BMS master uses the minimum and maximum cell voltage and temperature to determine whether charging or discharging should be enabled, as described in the following sections. The BMS is on and running whenever the EV is plugged in a wall outlet.

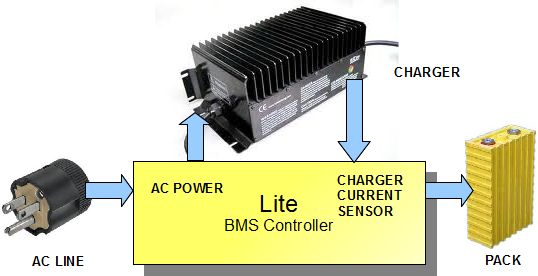

While the electric vehicle is plugged into the wall outlet, the AC power from the plug powers the BMS master through its "AC Power" connector. Inside the BMS master, as 12 V power supply powers the BMS. That voltage appears on all the "12 V" terminals on the control connector (they are powered whenever the EV is plugged in the wall or when the ignition switch is on). This supply can only provide enough power for the BMS master, plus a bit of current for external loads, such as small relays and indicator light bulbs. If any cell voltage is above the V-cell-max setting, or any temperature is outside the charging temperature range, the BMS turns off the charger, by switching off the AC voltage from the BMS master to the charger AC input. As soon as all cell voltages are back down to below the V-cell-high setting, and all the temperatures are within the charging temperature range, the BMS turns the charger back on. The EV MUST must be wired so that the BMS is able to shut off the charger As the BMS turn on the charger switch, it also turns on the "Charge OK" LED and sets the "CHG EN" output to 12 V. Conversely, as the BMS turn off the charger switch, it also turns off the "Charge OK" LED and opens the "CHG EN" output. The charger output current is routed through the "Charger Current Sensor" terminals before reaching the pack. Knowing the charging current allows the BMS master to:

Charging with a BMS and a CCCV charge occurs in 3 stages:

The Constant Voltage of the charger must be set to CV = number of cells in series x max cell voltage.

During this stage, the BMS keeps the AC switch turned on, to power the Charger. The charger operates in its CC (constant Current) mode, charging the pack at full current. The BMS increases the SOC. The first time the pack is charged, the BMS has no idea what the pack's initial SOC is: the SOC is uncalibrated. It will remain uncalibrated until the pack is fully charged for the first time. When powered up the first time, the BMS will assume an SOC of 50%. If the initial actual SOC had been less than 50%, at some point the calculated SOC will reach 100 %, even though the pack is still not full. On the other side, if the initial actual SOC had been more than 50%, the calculated SOC will be still be below 100 % by the time the pack becomes full. Once the voltage of the most charged cell reaches V-cell-max, the BMS enters the 2nd stage: balancing. During this stage, the BMS balances the pack. The point of balancing is to maximize the pack capacity, by ensuring that the cell with least capacity is the limiting factor to charging and to discharging. A pack is balanced if all of its cells are at exactly the same State Of Charge - at some point. In an EV, that point must be the top (fully charged). A BMS top balances the pack by removing charge from the most charged cells, to bring them down to the level of the rest of the cells. The Lithiumate BMS top balances the pack using the "final voltage" algorithm: it uses a cell's voltage near 100 % SOC to decides whether to remove some of its charge. Each cell board has a resistor load that can be placed across its cell to bleed off part of its charge, for the purpose of balancing the pack. In this stage, the BMS top balances the pack by:

This results in the charger switching on and off every few minutes. The on-off duty cycle is such that the average charge current is equal to the balance current. For example, with a 10 A charging current, and a 200 mA balance current, the charger may be on for 12 seconds, and off for 10 minutes. After each cycle of removing charge from the most charged cells (slowly, at about 200 mA) and adding charge to all the cells (fast, at on the order of 10 A), the cells' SOC levels are a bit closer to each other. After a number of cycles, all the cells are at the same SOC, all close to 100 %. The first time, this process can take as little as a few hours, or, if the pack was built with cells at significantly different SOC, as long as a few weeks. After a pack is balanced the first time, the BMS can keep it in balance in just a few minutes after each charge. Tip: to avoid having to wait a long time while the BMS does gross balancing the first time, balance the cells to each other before building the pack, by connecting them all in parallel for a few days. Once all the cells are at the same SOC (their voltages are all the same), the BMS enters the 3rd stage: topping off. In this stage, the charger operates in the CV (Constant Voltage) mode, maintaining its output at the voltage that it was set for: the voltage of a full pack. The BMS keeps the charger continuously on, but the charge current decreases exponentially to 0 as the pack voltage gets closer and closer to completely full. This reduction in current is not due to the BMS or to the charger: neither one is purposely decreasing the current. Instead, this effect is the result of the physics of the pack voltage reaching the charger's Constant Voltage setting: as they become closer, the voltage difference decreases, resulting in less and less current. When the voltage of each and every cell is exactly equal to V-cell-max, the charger current is down to 0 (because the pack voltage is the same as the charger's CV voltage, so there is no longer a voltage difference to cause any current). At that point:

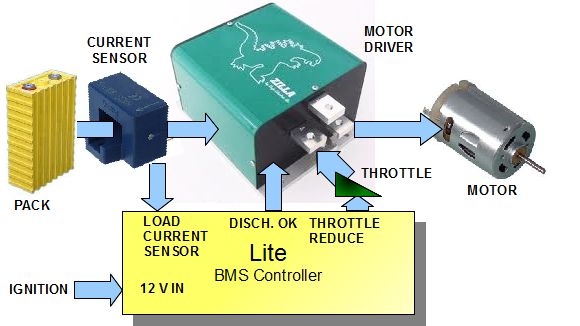

The BMS is on and running whenever the EV is on.

When the EV is on, the 12 V from the Ignition line powers the BMS through the "IGN" terminal in the control connector. That voltage appears on all the "12 V" terminals on the control connector (they are powered whenever the EV is plugged in the wall or when the ignition switch is on). The load current from the pack is routed through the cable-mounted Load Current Sensor before reaching the motor driver. Knowing the load current allows the BMS master to:

Ideally, the SOC will reach 0 % just as the lowest charged cell becomes empty. However, if the BMS is not configured properly, it may introduce errors in the SOC calculation; for example:

Even if the BMS is configured properly to calculate the correct SOC, if the EV is used aggressively, the cell voltages may sag considerably, and the BMS may shut off the pack before the SOC reaches 0% SOC. You cannot rely just on the reported SOC: in some cases the BMS may report a significant SOC level and yet shut down the pack because a cell voltage is too low; in other case, the BMS may report that the SOC is 0 %, yet the pack may be able to generate more charge. The only true indicator that the pack is nearing being empty is the voltage of the lowest charged cell. The BMS does not report that voltage directly to the driver. Instead, the BMS makes the user aware of that condition in ways described in the next section. Whenever any cell voltage is below V-cell-low, the BMS warns the user that the pack is nearly empty. It can do so in 2 ways, each of which may be implemented in an EV:

The "Reserve" indicator solution is least intrusive, but it relies on the driver reacting to the warning, which may not be wise. The onset of the "Valet mode" can be disconcerting to the driver, and may be dangerous if full power is needed at the time. The gradual reduction of throttle range is not sudden, which is nice, but may not be noticed when driving slowly. If, after a period of rest, all the cell voltages relax back up to above V-cell-low, the BMS will end the warning by opening the "LO BAT" line and bringing the Throttle Reduce output back to its minimum resistance. Whenever any cell voltage reaches V-cell-min, or any temperature is outside the range for discharging, the BMS tells the motor driver to shut off. It can do so by opening the "DCH EN" output (which normally would sit at 12 V). The EV can use that line in 3 ways:

The EV MUST must be wired so that the BMS is able to shut off the motor driver in one of the above ways. The BMS re-enables the motor driver once all cell voltages return to above V-cell-low, and all the temperatures are within the discharge range. As the BMS turns on and off the "DCH EN" output, it also turns on and off the "Discharge OK" LED. If the motor driver is capable of regenerative braking, it will extract energy from the car's motion and generate current to be sent back to the pack. That current flows through the load current sensor, in the reverse direction. The BMS master integrates that negative current into the SOC, increasing its value. When driving down a long mountain, regen will recharge the pack noticeably, and the SOC will increase towards 100 %. If the pack is full (a cell voltage is above V-cell-max), or a temperature is outside the range for charging, the pack cannot accept any more current. If so, the BMS will prevent regen, by opening the "CHG EN" line (which normally sits at 12 V). The EV can use that line in 2 ways:

The EV MUST must be wired so that the BMS is able to disable regen from the motor driver in one of the above ways. When all the cell voltages go back down below V-cell-high, and all the temperatures return within the range for charging, the BMS will re-enable regen by connecting the "CHG EN" line back to 12 V. The BMS master detects the following faults.

Should any of them last for a while[1], the BMS controller will go into a Fault state. In this state:

To reset the fault state, correct the problem. The delay is not a fixed number, but depends on the fault settings, on the severity of the problem and on other factors. For example, for discharge current, all of the following delays apply, one after the other:

For another example, for low cell voltage, all of the following delays apply, one after the other:

| ||

© 2008~2025 Elithion™, LLC. All rights reserved, except where noted by CC mark. Page published on May 07 2024.

The Elithion brand and the 'ə' (upside down 'e') logo are Trademarks of Elithion LLC. Graphic design by morninglori