Vinci-LV Li-ion Battery Management System ESS BMS for large, low voltage batteries and arrays

Outstanding versatility, feature rich Li-ion Battery Management System

24 to 48 V Energy Storage Systems (ESS)

Li-ion or lead acid

Arrays of up to 100 batteries in parallel

Complete: just add cells

Off the shelf, stocked, as low as $ 350

A member of the Vinci BMS family .

Vinci LV battery master

Applications

>

Stationary

Solar installations

UPSs

Telecomm sites

Computer server farms

Pole mount

Mobile

House power

Marine

Auxiliary Power Units (APU) for trucks

Aviation

Job-site power

Portable devices

For applications other than low voltage batteries, see other Vinci BMS families

Specifications

Single battery:

24 to 48 V

Up to 16 Li-ion cells in series

Any chemistry

2 to 4 lead-acid batteries (12 V) in series

Positive or negative ground, or isolated

Energy (@ 100 %) or power (@ 50 %)

Up to 16 strings permanently in parallel*

Array of batteries:

Up to 63 batteries in parallel

Safe connection to bus (no inrush)

Managed as a single unit

Li-ion and lead acid hybrid on same bus

Requires N+1 modules for N batteries

Physical:

Centralized (1 case)

Rugged, sealed, industrial grade packaging

Sensing:

Wired (voltage tap wires to cells)

Distributed (cell moudules on cells)*

Bullet-proof against tap mis-connection

Hall Effect or shunt current sensing

Up to 5 thermistors

Balancing:

Top or mid, SoC based

Dissipative ("passive")

Charge transfer (active)

Protector switch:

Isolated MOSFET gate drivers

Drivers for contactors or latching relay

Internal precharge

20 A internal protector*

20 A to 1000 A external sensors and protectors*

Evaluation:

SoC (State of Charge)

Pack isolation

Data logging

Communications:

Isolated CAN communication link

USB port for troubleshooting

Field configurable through GUI

One of:*

XanBus™

ModBus RTU (RS485)

ModBus TCP-IP (Ethernet)

RS232

WiFi (Access point or station)

(*) Option

XanBus is a trademark of Schneider Electric.

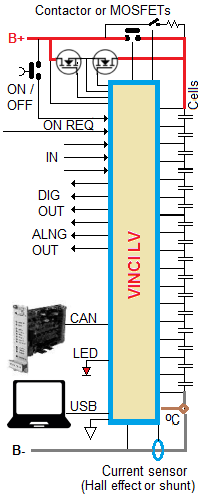

Block diagram

Examples

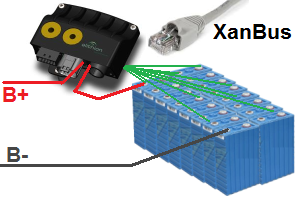

Single battery

16 LiFePo4 Li-ion prismatic cells in series: 48 V

20 A max current: protector switch inside BMS master

17 wires to the 16 cells to sense voltage

Fitted with optional XanBus™ interface for Scheider Electric invereter

48 V battery with XanBus™

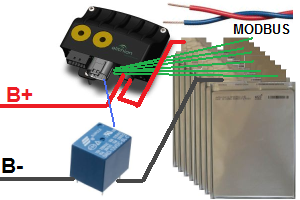

Single battery

7 NMC Li-ion prismatic cells in series: 24 V

50 A max current: current sensor inside BMS master, external contactor

Fitted with optional RS485 interface for MODBUS RTU

24 V battery with MODBUS

Single battery with 2 strings permanently connected in parallel

7 NMC Li-ion prismatic cells in series in each string: 24 V

20 A max current: protector switch inside BMS master

Each slave handles one string, with 8 wires to the 7 cells to sense voltage

Battery with parallel strings

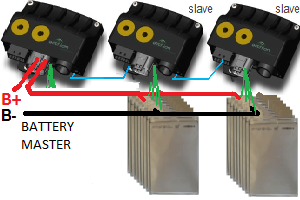

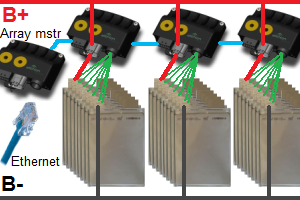

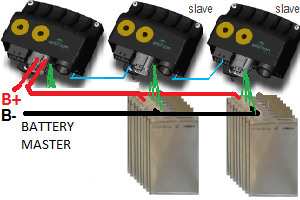

Array of 3 batteries

Array managed by an Array Master

Array Master fitted with optional RS485 interface for MODBUS RTU

Each battery managed by a Battery Master

Each string consists of 14 NMC Li-ion prismatic cells in series: 48 V

For each battery, 15 wires to the 14 cells to sense voltage

Battery array

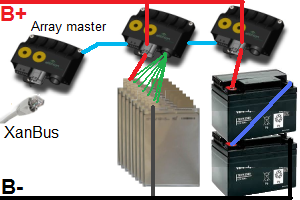

Array of mixed batteries

Array managed by an Array Master

Array Master fitted with optional XanBus™ interface for Scheider Electric invereter

Each battery managed by a Battery Master

First string consists of 7 NMC Li-ion prismatic cells in series: 24 V

For first battery, 8 wires to the 7 cells to sense voltage

Second string consists of two 12 V lead acid batteries in series: 24 V

For second battery, 3 wires to the 2 batteries to sense voltage

Mixed battery array

XanBus is a trademark of Schneider Electric.

Design & order your BMS

To design a BMS for your high voltage stationary battery, start by selecting one of these 2 topologies or contact us for help :

Wired, Centralized: A wire to each cell, one single module

Distributed, VinciBus: A module on each cell, fiber-optic to the Master

Wired, VinciLink: A wire to each cell, 2-wires between adjacent slaves; for strings permanently in parallel

Centralized topology

A single module performs all the BMS functions;

it senses cell voltages through a number of tap wires.

The BMS consists of:

A Centralized Battery Master

Up to 2 current sensors

A power switch (contactors or MOSFETs)

Optionally, to manage an array of batteries as a single unit, an Array Master

Detailed technical Info

Centralized topology

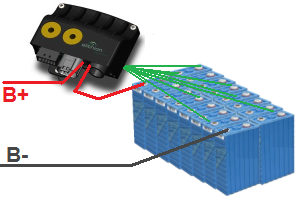

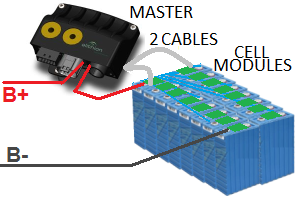

Distributed topology

A single Battery Master module performs most BMS functions.

A cell module is mounted on each prismatic cell to measure and report voltage and temperature.

The Battery Master is connected to the 2 cell module at the end of the battery through 2 small cables.

The BMS consists of:

A Centralized Battery Master

One cell module per cell

Up to 2 current sensors

A power switch (contactors or MOSFETs)

To manage an array of batteries as a single unit, an Array Master

Detailed technical Info

VinciLink topology

This topology is for batteries that have strings connected directly and permanently in parallel.

(If not, each string forms a separate battery, each requiring its own BMS.)

The BMS uses a Master/Slave topology, consisting of a Master and a number of modules;

communication between them is through a 2-wire daisy chain.

The Slaves sense cell voltages through a number of tap wires.

The BMS consists of:

A Battery Master

A number of VinciLink Slaves

Up to 2 current sensors

A power switch (contactors or MOSFETs)

To manage an array of batteries as a single unit, an Array Master

Detailed technical Info

VinciLink topology for strings in parallel

Which one?