|

|

|

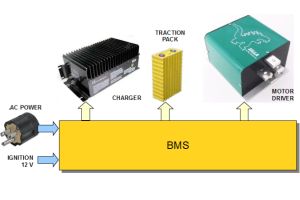

Lithiumate Lite Overview General description of the digital BMS for EVs | |

|

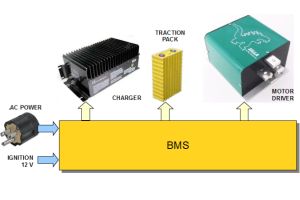

The BMS is powered:

- By the 12 V from the ignition, when the EV is on

- By the AC power whenever the EV is plugged into the wall

The BMS is connected to

- The traction pack

- The charger

- The motor controller

|

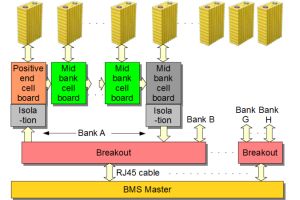

Overall block diagram

|

|

Measurement

- Measures and reports the cell voltages and temperatures in up to 8 banks of cells in a battery pack

- Measures and reports the battery pack current (bidirectional load current up to 900 A; charger current up to 30 A)

Evaluation

- Calculates and reports the State Of Charge of the battery pack

Management

- Balances the pack

- Dissipative (passive) balancing

- Top balance, voltage based

|

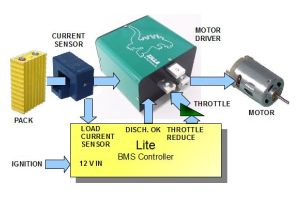

BMS in an application

|

|

Protection

- Turns off charger if any cell voltage exceeds a maximum, or the charging current is excessive

- Requests a reduction of motor drive if the battery is nearly empty

- Requests that motor controller be turned off if any cell voltage drops below a minimum, or the discharging current is excessive

- Disables charging and/or discharging if any cell's temperature is outside a range

- Disables charging and discharging if any cell board or bank stops reporting

- Prevents driving off when the vehicle is still plugged into the AC outlet

|

|

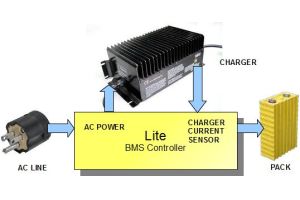

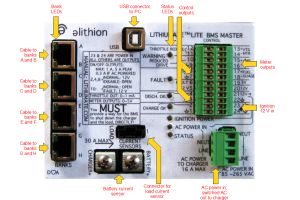

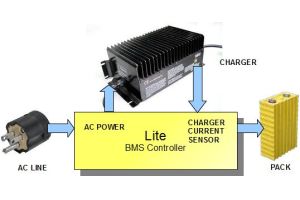

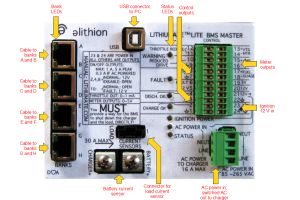

AC power connector

- AC Line input from the vehicle's AC plug (85 to 260 Vac)

- LED to indicate that AC power is present

Charger current sensor

- 30 Adc, charger DC output current sensor

No connector assembly required:

- AC power connector is 2-piece, screw clamp, terminal block

- Charger current sensor uses ring terminals mounted on screw terminals

|

Charger interface

|

|

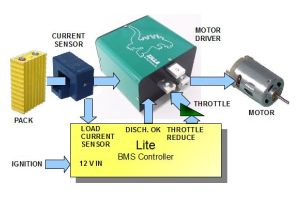

Ignition power input

- 12 V nominal, 50 mA nominal (no external loads)

- LED to indicate that Ignition power is present

Cable mounted current sensor

- Ready to plug-in

- Bidirectional, 900 A max

"Discharge OK" line, normally at 12 V, open when battery cannot deliver current

- Wire to the key input of the motor controller, or use to drive the main contactor

- Wire to a "Ready" lamp on dashboard

|

Vehicle traction interface

|

|

"Low Battery" line, normally at 12 V, open when battery charge is low

- Wire to the "Valet" input of the motor controller, to reduce available drive

- Wire to a relay to add resistance to the throttle, to reduce its range

- Wire to a "Reserve" lamp on dashboard

"Throttle Reduce" output, to reduce throttle range (2 or 3-wire pot, not HEPA)

- Insert in the "Wiper" line, between throttle and motor driver (for 3-wire throttle, a resistor must ve added)

- Wire to a relay to add resistance to the throttle, to reduce its range

- Isolated, for compatibility with motor drivers with pack referenced throttle

"Charge OK" line, normally at 12 V, open when battery cannot accept current

- Wire to the "Regen Enable" input of the motor controller, to disable regen

- Wire to brake pedal pot, to disable regen

"Fault" line, normally open, grounded when a fault is detected

- Wire to a "BMS fault" lamp on dashboard

- LED to indicate that there is a fault

No connector assembly required:

- Load current sensor comes with a connector

- Control connector is 2-piece, screw clamp, terminal block

|

|

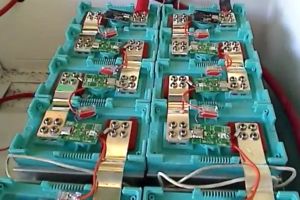

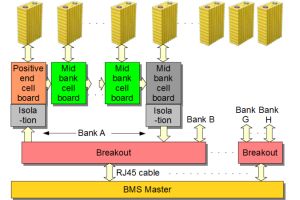

The BMS uses cell boards mounted directly on prismatic cells

- Up to 200 cells in series in a pack

- Divided into banks

- Each bank betweem 2 to 20 cells in series, recommended (users have used up to 25 cells)

- Cells directly in parallel count as one cell and use just inbe cell board

- Each bank has one positive end cell board, one negative end, and the rest are mid bank cell boards

- Each cell board measures its cell's voltage and temperature

- Posive end and negative end cell boards include an isolator, to isolate the high voltage of the pack from the 12 V supply

|

Block diagram of cell connections

|

|

Bank connectors

- Uses up to 4 each, RJ45 cables

- Each RJ45 cable connects the master to a breakout

- Each RJ45 cable and breakout handles 1 or 2 banks

- A breakout has 4 cables: two for positive end cell boards, 2 for negative end cell boards

No connector assembly required:

- Bank connections use off-the-shelf shielded RJ45 modular Ethernet cables (0.5 to 4 meters, as appropriate for the application)

- Complete modular cables are readily available from numerous sources

- Breakout at other end of modular cable is fully assembled

|

Traction pack interface

|

|

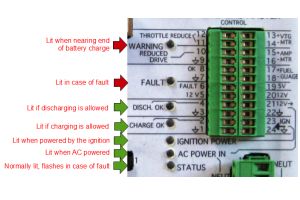

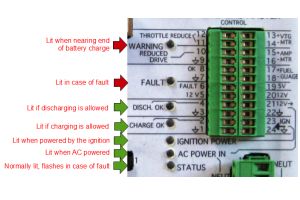

17 status LEDs on master

- "AC Power in": lit if powered by the AC line

- "Ignition power": lit if powered by the Ignition line

- "Charge OK": lit if charging is enabled

- "Discharge OK": lit if discharging is enabled

- "Warning": lit if the battery is nearly empty

- "Fault": lit if a fault was detected

- "Status": normally fully lit; in case of fault it flashes a code for the fault

- An LED for each bank indicates the satus of the communications for that bank

- Two LEDs by the USB connector flash when data is transmitted and received

|

Status LEDs

|

|

Three gauges on dashboard

- Drives standard fuel gauges (emulates fuel tank "sender")

- Configurable to match sender's characteristics (min and max resistance, direction)

- May be configured to drive a 5 V full scale meter

- Drives meters: battery current and voltage

- For 5 V full scale meters

- Full scale value configurable to match full scale on meter's face plate

- Designed to operate with popular Westach gauges

- Every controller LED function may be duplicated on dashboard with 12 V lamps

|

Ammeter, voltmeter, SOC meter

|

|

Graphics User Interface

- Computer based monitoring and configuration

- USB port for easy interface to the computer

- Uses a standard USB cable (no adapter dongle is required)

- Windows™ user interface

- Basic configuration takes only 4 steps

- One screen displays the complete status of the battery and the BMS

|

GUI application screen

|

|

AC power connector:

- AC power in, 85 to 265 Vac

USB connector:

- For connection to PC, during set-up and for troubleshooting

Current sensor connectors:

- Battery current sensor screw terminals, 30 A max

- Connector for prewired 900 A bidirectional load current sensor

|

Front panel

|

|

Bank connectors:

- 4 connectors, each for 2 banks

- Each connector has 2 LEDs, one for ach bank, to indicate its status

- Uses standard shielded RJ45 modular cables

Control connector: (clockwise from top)

Two-piece terminal block, screw clamps

- Meter outputs:

- Pack voltage meter, configurable range, for 5 Vfs voltmeter

- Pack current meter, configurable range (may go negative), for 5 Vfs voltmeter (may be bidirectional)

- Pack SOC meter, emulates fuel gauge sender, configurable resistance, or for 5 Vfs voltmeter

- Power outputs:

- 12 V when powered by the AC line (0.3 A max)

- 12 V when powered either way (1 A max if powered from the Ignition line, 0.3 A max if powered by the AC line)

- 5 V when powered either way (50 mA max)

- Power input:

- 12 V from the Ignition line

- Control outputs:

- Charge OK: normally 12 V, open if charging is not allowed

- Discharge OK: normally 12 V, open if discharging is not allowed

- Fault: normally open, 12 V in case of fault

- OK: normally 12 V, open in case of fault

- Warning: normally open, 12 V at the end of battery charge

- Throttle: normally open, gradually lower resistance at the end of battery charge

|

|

|